Katana Making Process: Clay Temper

In daily life, some customers who are not very familiar with swordsmanship often ask me what Hamon is on the blade? How did it come about. Here, I will give you a detailed introduction to the most important step in the process of Japanese sword making: the clay temper

What is Clay Temper?

Clay temper, also known as clay hardening or clay coating, is a technique used in the process of heat treating blades, particularly in swordsmithing. It involves applying a layer of clay to the surface of a blade before subjecting it to the heat treatment process of quenching and tempering.

The technique of clay tempering, known as "Yakiba" in Japanese, has a long history in the making of Katana swords. It is an essential aspect of traditional Japanese swordsmithing and has been practiced for centuries.

The origins of clay tempering can be traced back to ancient Japan, where swordsmiths sought to improve the performance and durability of their blades. The technique was refined and perfected over time, becoming a hallmark of Japanese swordmaking craftsmanship.

Why clay temper ?

- Differential Hardening: Clay tempering creates a contrast in hardness along the blade. By applying a layer of clay, different sections of the blade cool at different rates during the quenching process. The exposed sections cool rapidly, resulting in a harder martensitic structure, while the clay-covered sections cool more slowly, leading to a softer structure. This differential hardening creates a blade with a hard cutting edge and a more flexible spine, enhancing its overall performance and resilience.

- Strength and Flexibility: The combination of hard and soft areas achieved through clay tempering provides a balance of strength and flexibility in the blade. The hardened cutting edge allows for effective cutting and edge retention, while the softer spine increases the blade's durability and resistance to fractures. This balance is crucial for a blade to withstand the forces and stresses encountered during use.

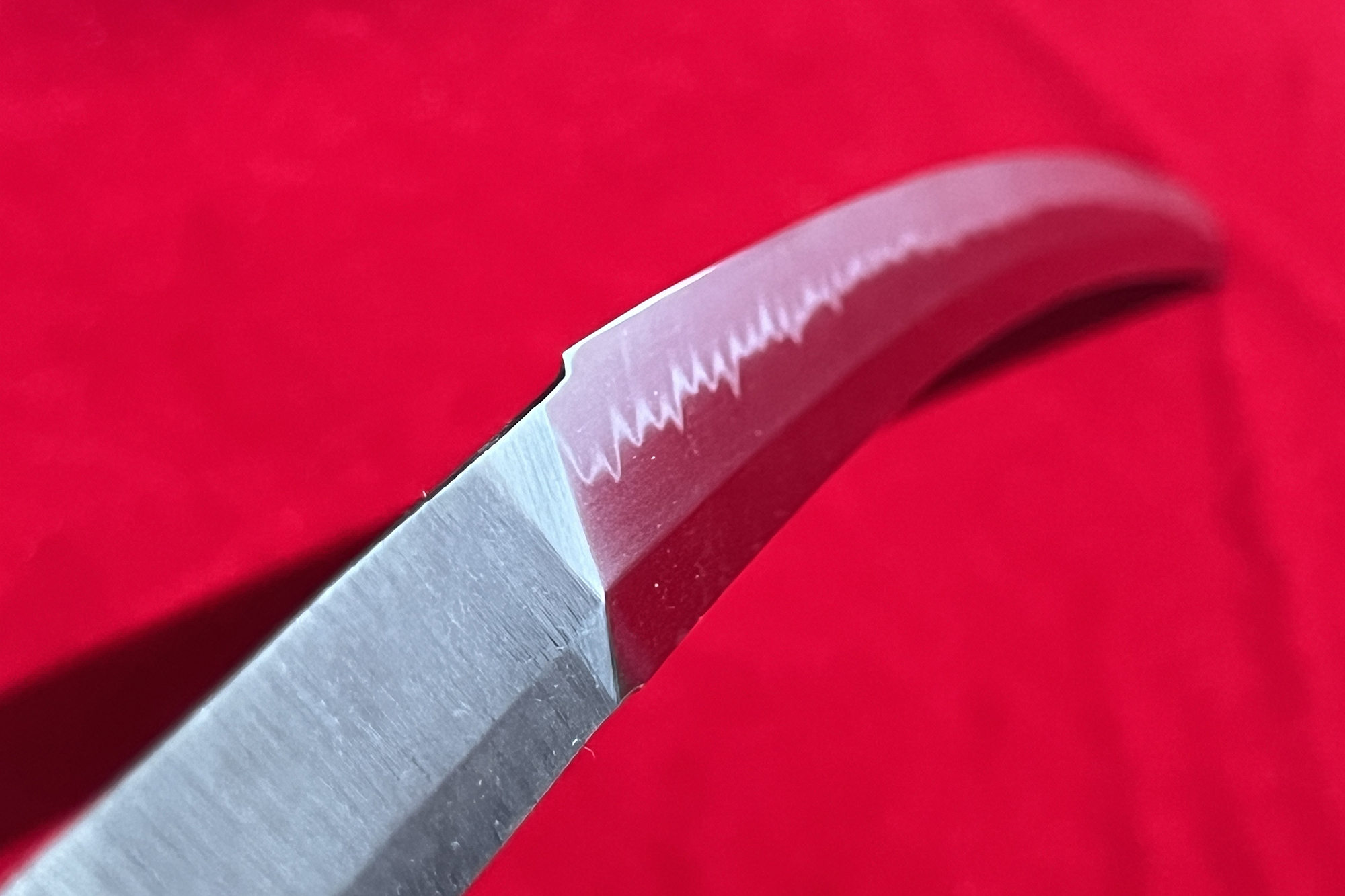

- Hamon Pattern: Clay tempering produces the visually striking hamon pattern, also known as the temper line. This pattern is revealed through polishing and etching the blade after tempering. The hamon adds aesthetic appeal to the blade and is considered a hallmark of traditional Japanese swordsmithing. It represents the transition between the hardened edge and the softer spine.

- Tradition and Artistry: Clay tempering has been used in blade making for centuries, particularly in the crafting of Japanese swords. It is an integral part of traditional swordsmithing techniques and reflects the artistry and craftsmanship associated with these blades. Clay tempering allows swordsmiths to create unique and individualized blades with distinct temper line patterns, making each blade a work of art.

Clay Tempering Process:

1. Blade Preparation:

- Start by forging the blade to the desired shape and thickness. Ensure that the blade is properly shaped and free from any defects or imperfections.

2. Clay Application:

- Prepare the clay mixture by combining clay, water, and sometimes other materials like powdered charcoal or ash. The specific clay mixture may vary depending on the desired outcome and the traditions followed by the swordsmith.

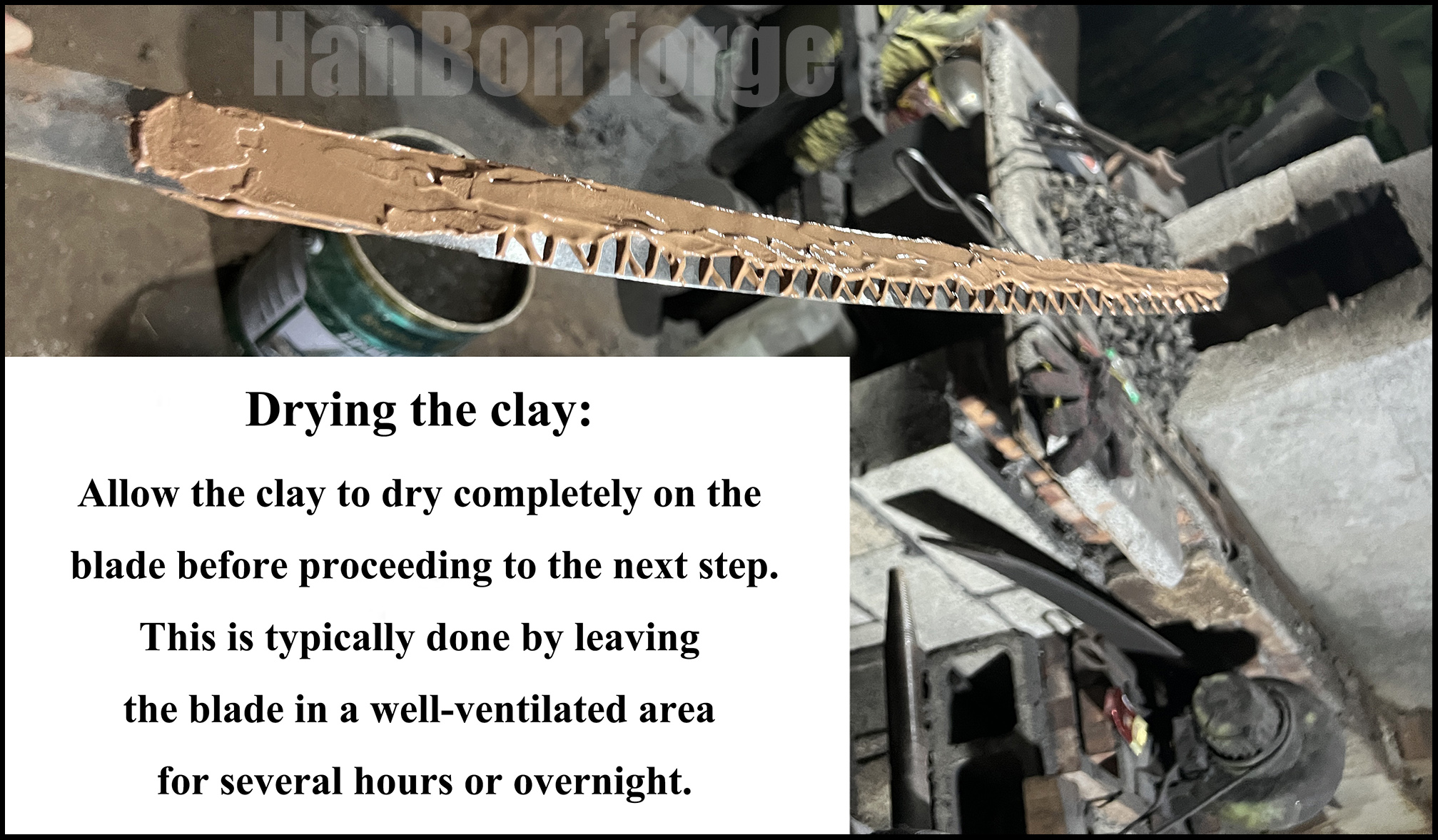

- Apply a thin, even layer of clay to the blade's surface using a brush or spatula. The thickness and coverage of the clay layer will determine the resulting hardness variations.

3. Drying:

- Allow the clay-coated blade to dry completely. This step is crucial to ensure that the clay adheres firmly to the blade and does not crack or peel during the subsequent heating and quenching process.

4. Heating:

- Heat the blade in a forge or furnace to a critical temperature known as the austenitizing temperature. This temperature is specific to the type of steel used and typically ranges between 750°C and 850°C (1382°F and 1562°F).

- The heat treatment transforms the steel's microstructure into austenite, a high-temperature phase that allows for the subsequent hardening and tempering processes.

5. Quenching:

- Once the blade has reached the austenitizing temperature, carefully remove it from the heat source and transfer it to a quenching medium, such as oil, water, or brine. The choice of quenchant depends on the type of steel and desired blade properties.

- The rapid quenching rapidly cools the blade, causing a martensitic transformation, which results in a hard, brittle structure.

8. Final Finishing:

- Once the tempering process is complete, the blade is carefully cleaned, polished, and often etched to reveal the distinct hamon pattern. This pattern showcases the transition between the hardened and softer areas of the blade, adding to its aesthetic appeal.

Important tips:

- Clay Composition: The composition of the clay used for tempering is crucial. Different types of clay, such as natural clays or specially formulated mixtures, can yield varying results. It is important to select a clay mixture that is suitable for the desired hardness and flexibility of the blade.

- Thickness and Application: The thickness and application of the clay layer on the blade require careful attention. The thickness determines the rate of heat transfer during quenching. Thicker clay layers result in slower cooling, while thinner layers lead to faster cooling. The clay should be evenly applied and free from any air pockets or gaps to ensure consistent heat distribution.

- Clay Patterns: The patterns created with the clay layer significantly impact the resulting blade's aesthetics and performance. The placement and design of the clay patterns determine the distribution of hardness and flexibility along the blade. The patterns should be carefully planned and executed to achieve the desired outcome.

- Heat Treatment: Proper heat treatment is essential for successful clay tempering. The blade needs to be heated to a specific temperature before quenching. The temperature and duration of the heating process should be carefully controlled to achieve the desired hardness and structure in the blade.

- Quenching Medium: The choice of quenching medium plays a significant role in the clay tempering process. Typically, water or oil is used for quenching. The selection of the quenching medium depends on factors such as the type of steel used and the desired hardness. It is important to follow proper quenching procedures to achieve the desired blade qualities.

- Experience and Expertise: Clay tempering requires skill, experience, and expertise. It is a complex process that demands a deep understanding of materials, heat treatment, and blade geometry. It is advisable to learn from experienced swordsmiths or experts in the field to ensure proper execution and desirable results.

- Quality Control: Throughout the clay tempering process, quality control is crucial. Regular inspections and adjustments may be necessary to ensure the clay layer's integrity, thickness, and uniformity. Additionally, post-tempering inspections, such as hardness testing and visual examination, help assess the success of the tempering process.

The video of the clay temper process----HanBon Forge

In conclusion, the clay tempering process is an integral and fascinating part of Japanese swordmaking. It not only enhances the performance and durability of the katana but also adds to its aesthetic appeal. By creating a differential hardness along the blade, clay tempering provides a balance of strength and flexibility, making the sword capable of withstanding the forces and stresses of combat.

For those interested in owning a katana, understanding the clay tempering process provides insight into the craftsmanship and artistry behind these iconic weapons. Whether as a functional tool or a work of art, a clay-tempered katana represents the culmination of centuries of tradition and skill.

Aspiring sword enthusiasts are encouraged to learn from experienced swordsmiths or experts in the field to ensure proper execution and desirable results. With dedication, patience, and a deep appreciation for the craft, one can embark on a journey to own a truly exceptional katana, steeped in history and cultural significance.

At HanBon Forge, we offer a wide selection of katana swords, including clay-tempered blades, crafted by skilled artisans. Feel free to explore our collection and embark on your own journey into the world of Japanese swordmaking.

Leave a Comment